Industrial Decarbonisation - Materials & Manufacturing Showcase 2025 Event

What does £1.75bn of innovation investment in the UK materials & manufacturing sector look like?

Rather than short-changing you and those companies that I found particularly interesting from the event with a quick link in the newsletter, I thought a longer update would be appreciated. Catchy title aside, it was certainly worth a visit!

Location?

A nice spot to visit for the day in London - having walked over Millenium Bridge, after a quick stroll down the Southbank, we were located at a very nice event space behind the spectacle that is St. Pauls in Paternoster Square. You forget how fantastic this building is, and the scale of it.

And the Event?

This is an annual event bringing together UKRI programmes and partners from across UK industrial disciplines, to accelerate decarbonisation and next-generation technologies in materials & manufacturing. ⚙️

With a multi-year £1.75bn investment into materials & manufacturing to showcase, across 50 exhibitors, 1,000 delegates, and some great panel sessions, there was a lot to get involved with! 👀

I'm not going into all of it, there was far too much going on - a lot of panel sessions across multiple rooms that were impossible to juggle while chatting to the various startups, scale-ups, academia and investors that were there.

Train delays 😡 meant I missed some of the early keynotes, and a couple of the panel sessions - the upside was more time on the exhibitor floor.

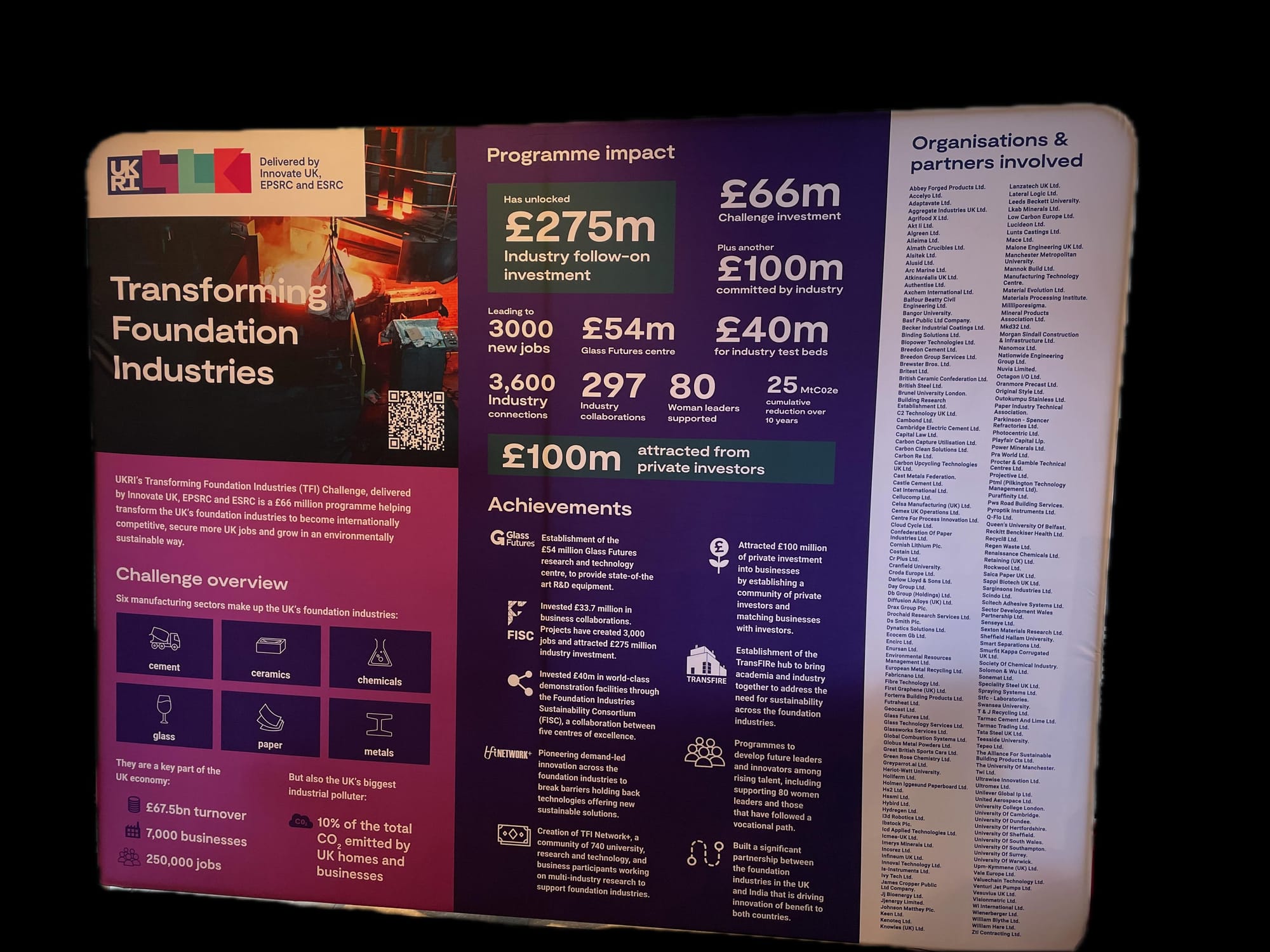

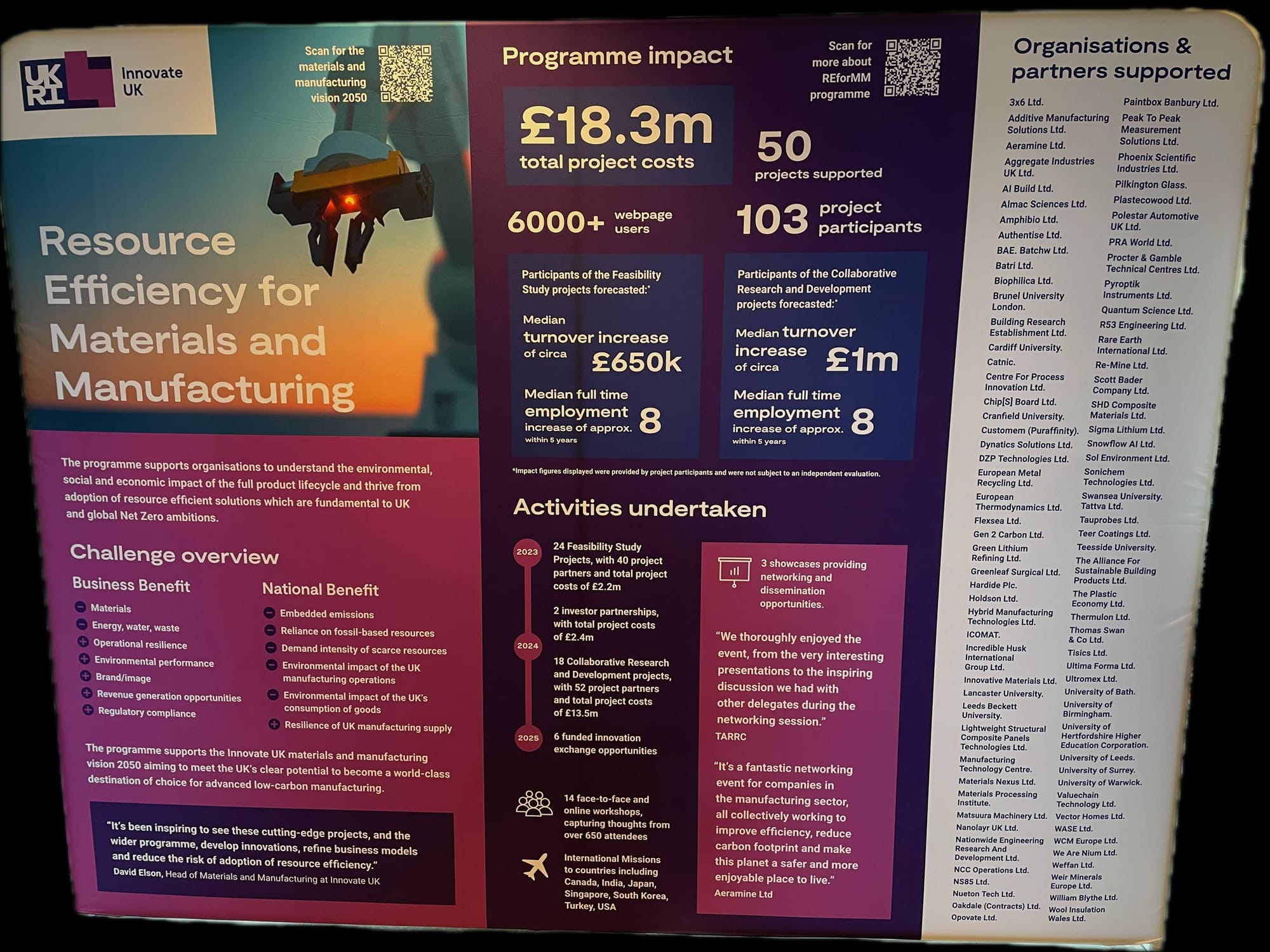

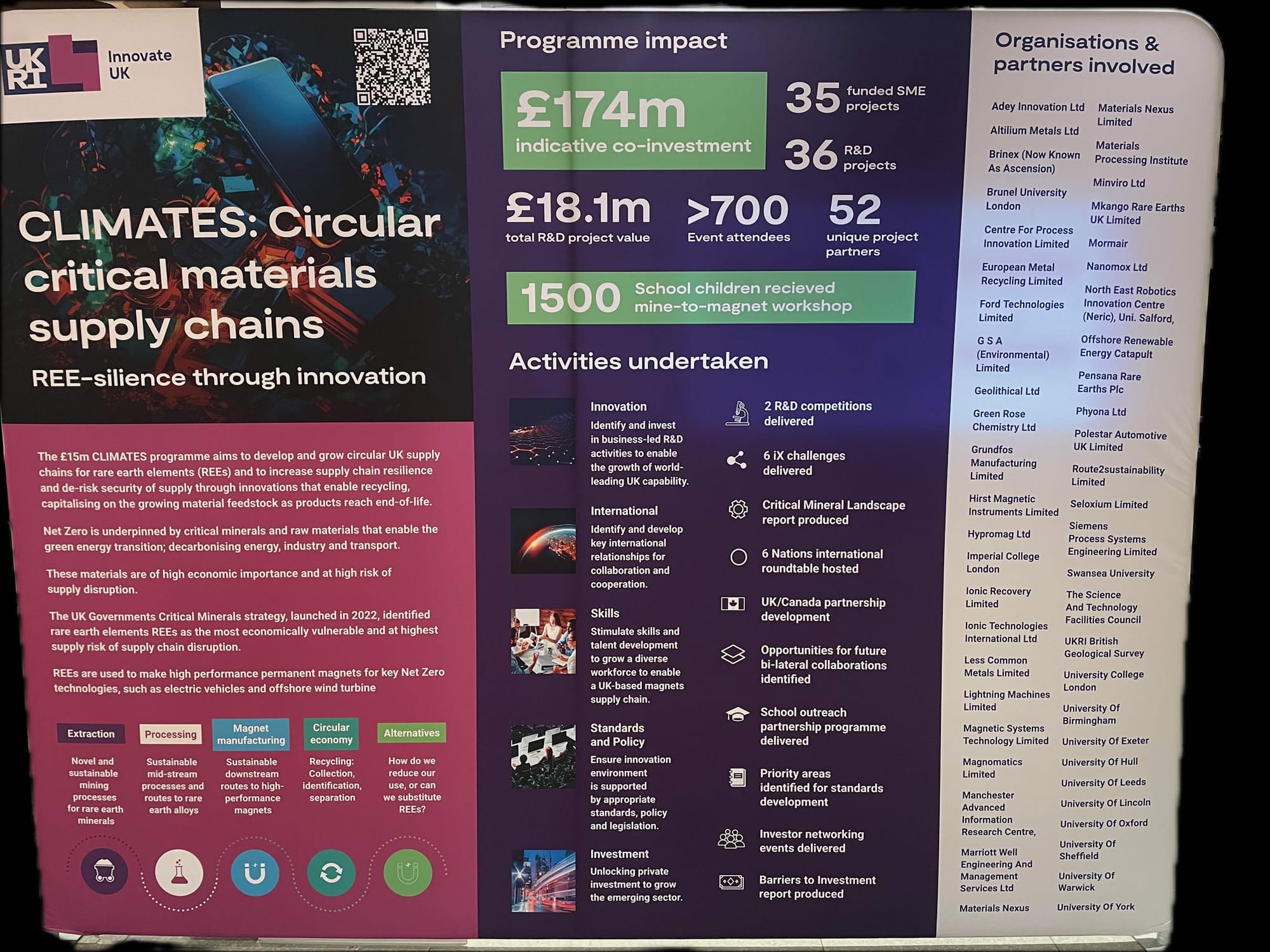

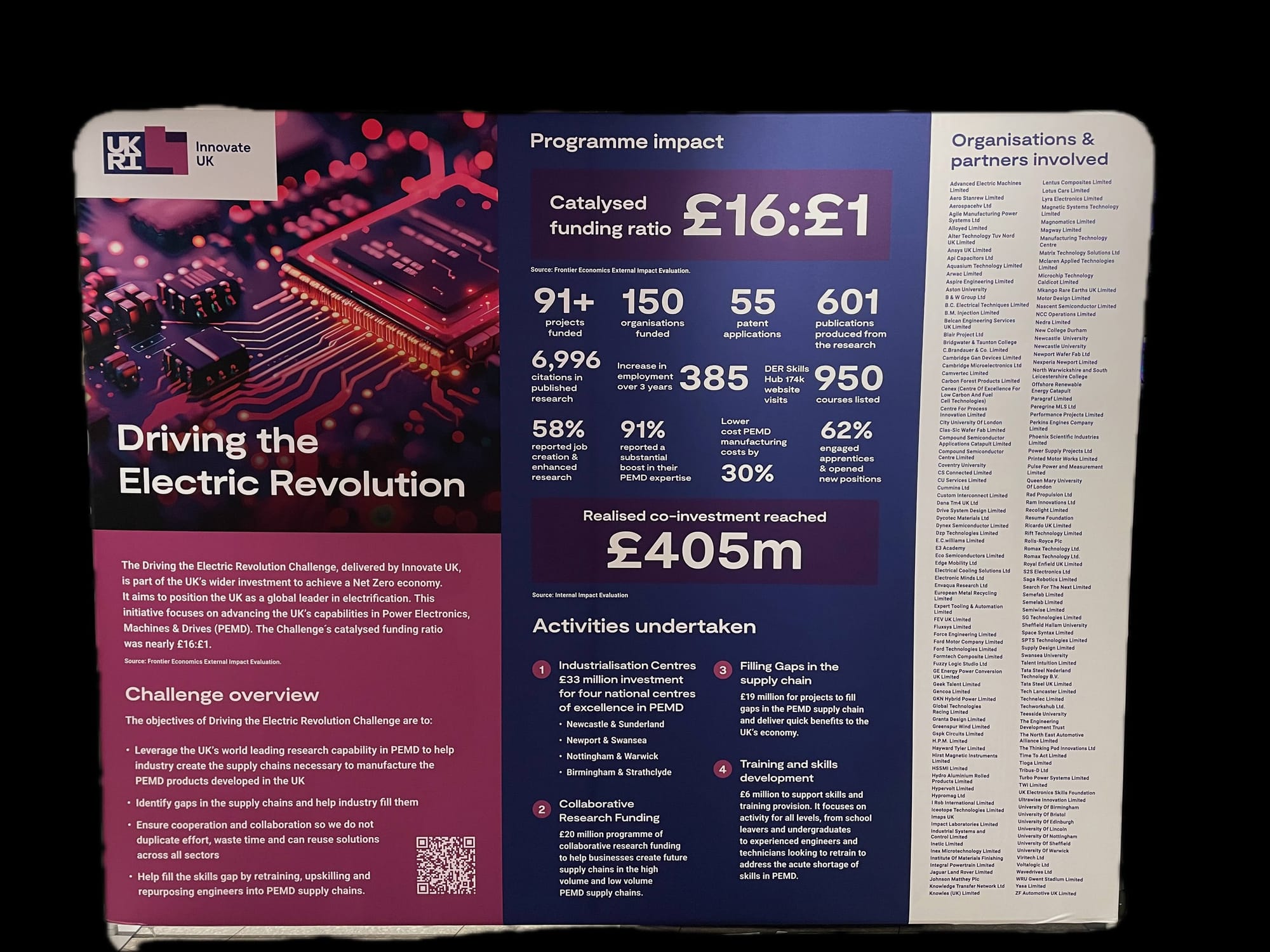

Some snapshots of the programmes [there were 6 in all] that had been involved in delivering this innovation:

No chance of forgetting the event - I have to say the catering was 'Bellissimo' for an event with such a volume of delegates, bravo 👨🍳 😋

Highlights?

Well, it was entirely about innovation, so it was all good - a few of my favourites are highlighted with some context.

From the panel sessions, in particular, I enjoyed the 'Role of Digital Twins' with some great insights into the development and utilisation of the technology from GreyParrot and Artemis Technologies.

Unfortunately, I missed the Transforming Foundation Industries Challenge and the FOAK / Scaling session which included Materials Evolution but got to talk to them directly afterwards - what a nice bunch they are. 👏

The final session of the day was the 'What does 2050 look like' crystal ball time. A fun and expansive thinking end-point with some good stuff from Matta and AEM listed below, plus a £500bn UK opportunity to move us away from petro-chem and plastic-based solutions to bio-based from Dr Jen Vanderhoven from the Bio-base and Biodegradable Industries Association, BBIA. 🔮

Here we go then:

GreyParrot

Digital twin technology for waste processing. Waste analyser units with computer vision technology and AI integration create a digital twin and 95% coverage of waste stream conveyor lines across 89 material categories of municipal waste.

❓Why it matters

We aren't that good at identifying and recycling our municipal waste and plastics. This captures not only material composition but also mass, brand, food grade, value and emissions scope. 👁️

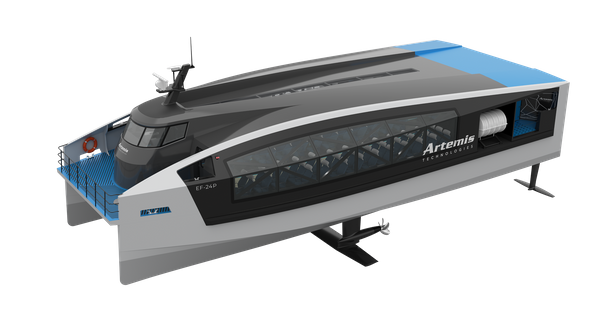

Artemis Technologies

Electrification of high-speed marine transport. From pilot and workboats through to the new 150-seat passenger craft.

❓Why it matters

Particularly exciting as it's a spin-off from the professional sailing team and America's Cup 2010 campaign using all that technology and foiling data - a $200m R&D programme! Fascinating for me to revisit and see the next-gen outcomes, as I used to supply AC teams [2000-07] with equipment and high-performance materials.

There are a lot of passenger ferries and workboats around the world, and they all eventually need to switch from fossil fuel to battery power. Just as importantly, this product range entirely swerves hydrogen fuel. Hoping to see one on the Southampton-Isle of Wight route someday soon! ⛴️

MaterialsInformation

Material data meets big-data, and LLM meets AI, meets blockchain. Early phase start-up with some big-ticket client traction, and in the process of raising some investment.

❓Why it matters

Huge opportunity to optimise efficiency, performance and decarbonise material selection through a platform which envelopes chemistry, form, supplier and origin, batch and treatment information. Think of that in an interactive and responsive rather than a static database, add in ledger IP and security and it's quite the complex SaaS materials solution across multiple sectors and applications. ⚙️

Advanced Electric Machines

Electric motors, but without the copper and magnets.

❓Why it matters

We need a lot of electric motors, and we need them to cost less, be more efficient, recyclable, and contain fewer resources such as copper which reduces supply chain emissions and processing. These are lighter, more efficient, and increased RPM up to 30,000! 🚗

People Led Digitalisation

It's always about the people. Fascinating collaboration between academia and industry to ensure people are core the the industry 5.0 revolution.

❓Why it matters

As technology and AI adoption means drastic changes in the manufacturing and industrial workplace, PLD deliver valuable insights and practical tools for digital engagement – driving sustainable, ethical and effective digital transformation that delivers for people and businesses. 🧑🤝🧑

Pulpex

It's not plastic - cellulose fibre-based, fully recyclable, and no plastic liner either!

❓Why it matters

There are a lot of plastic drink bottles in the world. They just landed a Series-D £62m investment and have a new factory in Glasgow in the works. With the blue-chip drinks and packaging players already involved, a global licensing model, this really could scale. 📈

Matta

The AI factory of the future - detect, optimise, control, digital twin, efficiency and all that good stuff.

❓Why it matters

Starts with a low-cost equipment entry point - standard web-cam type cameras deployed around the factory. Clever AI agents learn factory inspection and QC process and production tolerances to improve throughput and efficiency - then facilitate reverse-engineering optimisation of production processes. Very clever indeed. 🧠

Materials Evolution

Low-carbon cement - because it's a big global problem. Alkali fusion technology eliminates the need for heat = <energy consumption. CO2 emissions reduced to 144-196kg of CO2e per/tonne for up to -85% reduction vs traditional cement.

❓Why it matters

Cement is an epic challenge. 8% of all global emissions come from the cement industry, while 80% of concrete emissions come from cement production. And there is a lot of it - the second most used commodity globally after water. 🤯

Wrap-up

My apologies to those not included; there were far too many great innovations and technologies on-site. For those that didn't attend the day, they were served by some robots 🤖 with iPads for Zoom calls, which was quite cool!

The whole event was a fantastic testimony to the work that UKRI, Innovate UK and Business Connect programmes in combination with MAKE UK and the High-Value Manufacturing Catapult.

Look forward to tracking these companies and technologies as they start to move through the investment rounds and take steps to scale.

If anyone is interested in connecting, collaborating or investing, please message me directly and I can arrange an introduction to key connections from these featured organisations.

Perhaps I can get a couple of them on for an interview 🎙️ 🤔